Overview

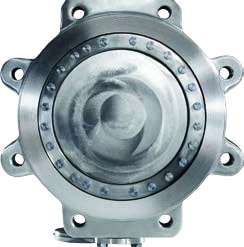

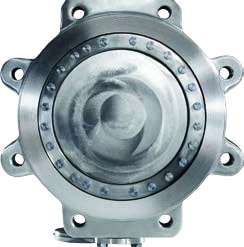

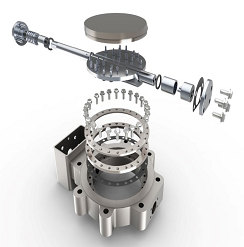

Baker Hughes’s Masoneilan 33000 Series incorporates patented design with advanced manufacturing to provide high performance, triple offset features that enables bi-directional, isolation tight shutoff under a wide range of pressures and temperatures for both control and on/off applications. The 3rd offset angle of the disc, along with a metal-to-metal seating surface, allows for minimal friction to enable isolation tight shutoff while used in both on/off, as well as high throttling, control valve applications. The heavy duty 33000 series butterfly valve provides the high degree of zero leakage performance, with a less costly design as compared to the larger gate, globe or ball valve technologies used in many isolation applications.

Features & Benefits

The advanced design and manufacturing processes of the 33000 Series incorporates high performance, triple offset enhancing features into traditional butterfly valve technology to provide superior performance within a light weight platform.

Low Friction, Zero Leakage

Our patented seat and seal technology makes for a more reliable valve using a robust metal-to-metal seal to achieve API 607 and ISO EN 10497 fire resistant certification, while achieving zero bi-directional leakage. Advanced manufacturing of the seating components into an offset conical design allows for minimal friction while throttling, until the final moment of closure as the valve seat comes in contact with the disc.

Full Capacity Cv

A design focused on circular conical sealing technology means a better, low-friction seating with maximum flow capacity (Cv). Traditional designs use elliptical seals, which create greater drag, friction, and flow profile interference, resulting in increased wear and a reduction of total flow capacity of the valve.

Low Emissions

The 33000 series is qualified to EPA Method 21 certified low leak (Low-E) and ISO fugitive emission specifications following ISO-15848 under both helium and methane conditions. The rotary motion of a butterfly valve inherently introduces less external debris (dust) into the packing box compared to a linear valve, and produces less wear against sealing components to ensure longer term emissions reduction.

Specialty Applications

Designed with metal-to-metal seats, and optional extended bonnet design, the 33000 series is ideal to maintaining zero leakage performance under harsh conditions, including LNG cryogenic conditions (-196 C), and fire resistant environments requiring API 607 and ISO EN 10497 certification.

Less Downtime

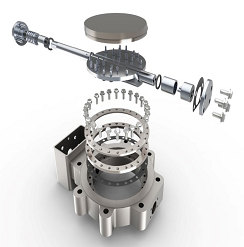

When the time comes to carry out essential maintenance, the Masoneilan 33000 Series design pays massive dividends. Field replaceable seat rings and a 2-piece disc design allows for quick inspection, removal and replacement without disassembly; saving you valuable plant downtime.

The 33000 Series Triple Offset Butterfly Valve incorporates new performance enhancing operational features including:

Sizes:

3" through 48" (80 through 1200 mm)

Ratings: ASME CL150 – CL600

Connections:

Wafer, Lugged, Raised Face Flanged, RTJ Optional, EN Flange

Body Face to Face:

Wafer and lugged bodies API 609 Table-3 (A) (Category B Valves up to 24”)

Double flanged short pattern: API609 table 3 (C) (Category B Valves up to 24”)

o Class 150: dimensions per ISO 5752 Basic series 13, EN 558-2, EN 593

o Class 300: dimensions per ISO 5752 Basic series 14, EN 558-2, EN 593

Body Materials:

Carbon steel WCC, Stainless steel CF8M, Low Temperature Carbon Steel LCC, Others on request

Trim: Triple Offset

Seat Leakage:

Class IV (Standard) per IEC 60534-4 &ANSI/FCI 70-2

Class V & VI (Optional) per IEC 60534-4 &ANSI/FCI 70-2

Zero Leakage (API 598)

Inherent Characteristics:

Equal percentage

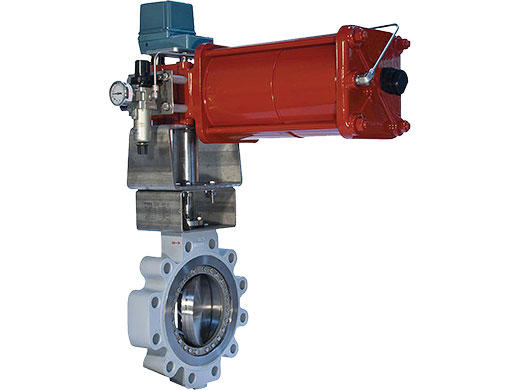

Actuator:

Spring-Diaphragm, Scotch Yoke Piston, Manual Gear, Others on request